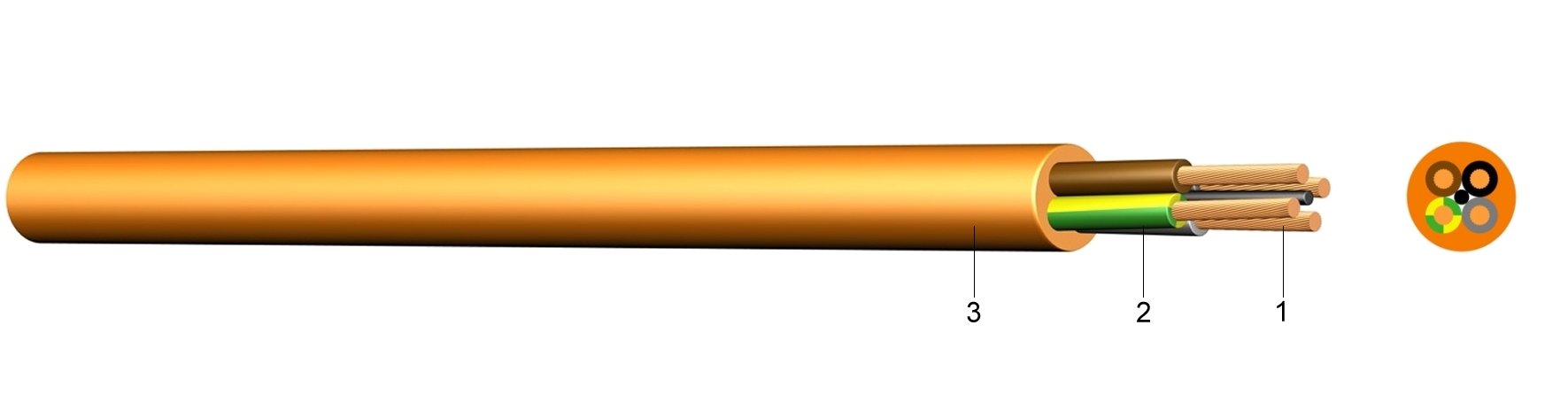

H07BQ-F | Polyurethane Building Site Cable with Rubber Insulated Conductors

Item descriptions

| Application: | This termination and connection cable with high mechanical stress-resistance can be used in dry, damp or wet rooms as well as in the open-air. It is ideal for application in industrial plants, building sites, in fact everywhere where extreme wear and tear resistance is required and where the cable is subjected to hard utilisation. |

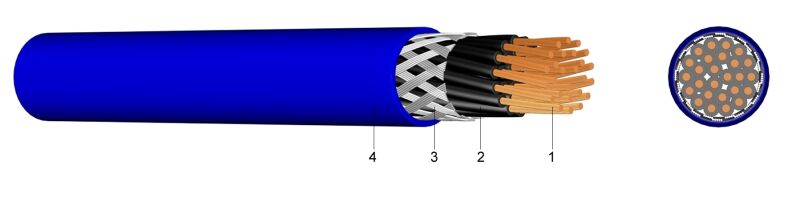

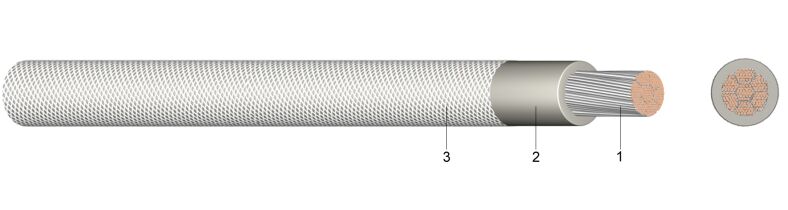

| Construction: | 1.....fine-stranded tinned or bare copper 2.....core insulation of a rubber compound (EL6) 3.....outer sheath of polyurethane (PUR), orange |

| Standards: | DIN VDE 0282-10 HD 22.10 S1+A1 DIN EN 60228 class 5 (construction) HD 308 S2 (core identification) |

| Nominal voltage Uo/U | [V] | 450 / 750 Volt | |

| Test voltage | [V]AC | 2500 | |

| Temperature range | in motion | -40°C till +90°C | |

| Operating temperature | short circuit | °C | 200 |

| Short circuit time | max. | [sec] | 5 |

| Bending radius | one time / fixed | x diameter | 4 |

| in motion | x diameter | 5 | |

| Oil-resistant | standard | EN 60811-2-1 | |

| Flammability | standard | EN 60332-1-2 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 2 X 1,5 | 28,80 | 30 x 0,26 | 8,8 | 88 |

| 3 G 1,5 | 43,20 | 30 x 0,26 | 9,3 | 110 |

| 4 G 1,5 | 57,60 | 30 x 0,26 | 10,3 | 140 |

| 5 G 1,5 | 72,00 | 30 x 0,26 | 11,2 | 169 |

| 3 G 2,5 | 72,00 | 50 x 0,26 | 11,0 | 163 |

| 4 G 2,5 | 96,00 | 50 x 0,26 | 12,2 | 208 |

| 5 G 2,5 | 120,00 | 50 x 0,26 | 13,5 | 257 |

| 5 G 4 | 192,00 | 56 x 0,31 | 15,6 | 365 |

| 5 G 6 | 288,00 | 84 x 0,31 | 17,6 | 504 |

| 5 G 10 | 480,00 | 80 x 0,41 | 23,2 | 962 |

| 5 G 16 | 768,00 | 128 x 0,41 | 27,1 | 1.379 |

| 5 G 25 | 1.200,00 | 200 x 0,41 | 33,3 | 2.169 |

| without filling compound | ||||

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 2 X 1,5 | 28,80 | 30 x 0,26 | 8,8 | 88 |

| 3 G 1,5 | 43,20 | 30 x 0,26 | 9,3 | 110 |

| 4 G 1,5 | 57,60 | 30 x 0,26 | 10,3 | 140 |

| 5 G 1,5 | 72,00 | 30 x 0,26 | 11,2 | 169 |

| 2 X 2,5 | 48,00 | 50 x 0,26 | 10,4 | 129 |

| 3 G 2,5 | 72,00 | 50 x 0,26 | 11,0 | 163 |

| 4 G 2,5 | 96,00 | 50 x 0,26 | 12,2 | 208 |

| 5 G 2,5 | 120,00 | 50 x 0,26 | 13,5 | 257 |

| 3 G 4 | 115,20 | 56 x 0,31 | 13,1 | 236 |

| 4 G 4 | 153,60 | 56 x 0,31 | 14,0 | 293 |

| 5 G 4 | 192,00 | 56 x 0,31 | 15,6 | 365 |

| 4 G 6 | 230,40 | 84 x 0,31 | 15,2 | 346 |

| 5 G 6 | 288,00 | 84 x 0,31 | 17,6 | 504 |

| 4 G 10 | 384,00 | 80 x 0,41 | 20,2 | 702 |

| 5 G 10 | 480,00 | 80 x 0,41 | 23,2 | 962 |

| 4 G 16 | 614,40 | 128 x 0,41 | 22,8 | 981 |

| 5 G 16 | 768,00 | 128 x 0,41 | 27,1 | 1.379 |

| 5 G 25 | 1.200,00 | 200 x 0,41 | 33,3 | 2.169 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 07BQ-F | ||||

| 7 G 1,5 | 100,80 | 30 x 0,26 | 14,0 | 291 |

| 7 G 2,5 | 168,00 | 50 x 0,26 | 16,5 | 431 |

| 12 G 1,5 | 172,80 | 30 x 0,26 | 18,0 | 446 |

| 12 G 2,5 | 288,00 | 50 x 0,26 | 21,0 | 641 |