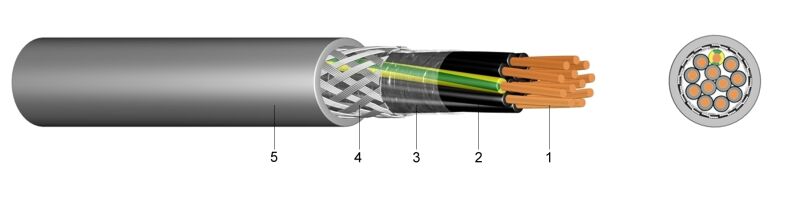

YSLCY | PVC Control Cable with Copper Braiding

Item descriptions

| Application: | Suitable as a signal and impulse cable in the control, measuring and signal technology. The copper braiding optimises protection against external interferences, like electromagnetic fields and stray frequencies. |

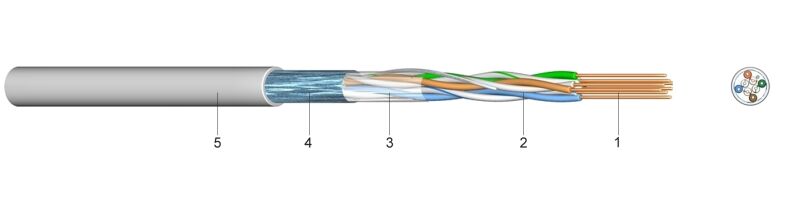

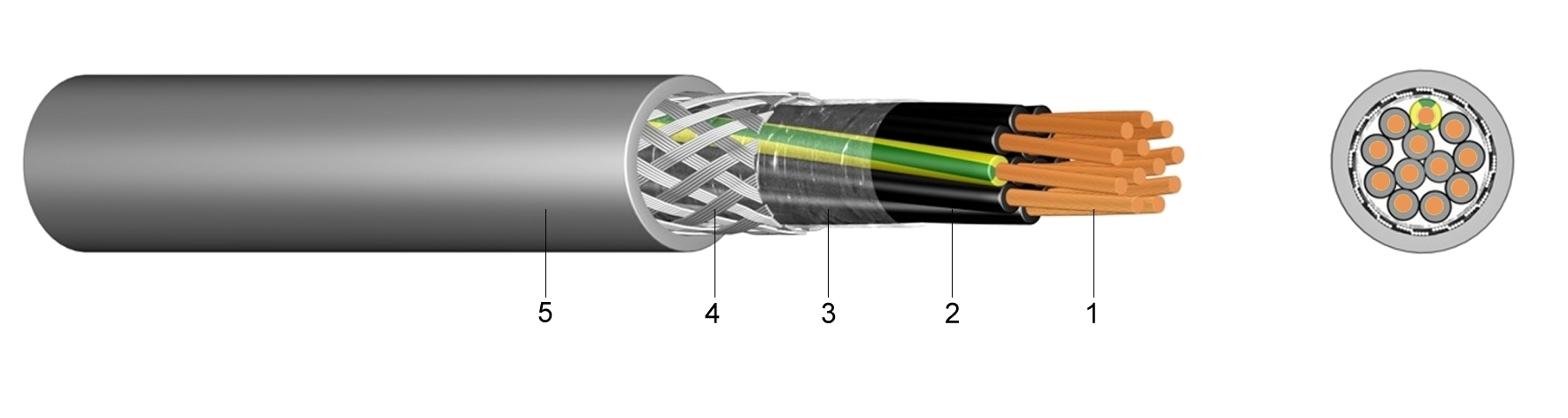

| Construction: | 1.....fine-stranded bare copper 2.....core insulation of polyvinylchloride (PVC) 3.....wrapped in a plastic foil 4.....braiding of tinned copper round wires 5.....outer sheath of polyvinylchloride (PVC), grey, increased oil resistant |

| Standards: | adapted to DIN VDE 0281 DIN EN 60228 class 5 (construction) HD 308 S2 (core identification for coloured cores) core identification JZ: 1 core green/yellow, other cores black with figures core identification OZ: every core black with figures |

| Nominal voltage Uo/U | [V] | 300 / 500 Volt | |

| Test voltage | [V]AC | 2000 | |

| Temperature range | in motion | -5°C till +70°C | |

| fixed | -30°C till +70°C | ||

| Operating temperature | short circuit | °C | 150 |

| Short circuit time | max. | [sec] | 5 |

| Bending radius | one time / fixed | x diameter | 10 |

| Bending radius | in motion | x diameter | 20 |

| Flammability | standard | EN 60332-1-2 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (app.value) mm | Overall diameter appr.mm | Weight appr. kg / km | |||

| 2 x 0,5 | 34,56 | 16 x 0,21 | 5,6 | 45 | |||

| 3 x 0,5 | 41,28 | 16 x 0,21 | 5,9 | 55 | |||

| 4 x 0,5 | 47,04 | 16 x 0,21 | 6,4 | 73 | |||

| 5 x 0,5 | 54,72 | 16 x 0,21 | 7,0 | 91 | |||

| 12 x 0,5 | 99,84 | 16 x 0,21 | 9,8 | 208 | |||

| 25 x 0,5 | 202,56 | 16 x 0,21 | 13,7 | 354 | |||

| 2 x 0,75 | 41,28 | 24 x 0,21 | 6,2 | 56 | |||

| 3 x 0,75 | 49,92 | 24 x 0,21 | 6,5 | 70 | |||

| 4 x 0,75 | 58,56 | 24 x 0,21 | 7,0 | 96 | |||

| 5 x 0,75 | 69,12 | 24 x 0,21 | 7,8 | 157 | |||

| 7 x 0,75 | 85,44 | 24 x 0,21 | 8,4 | 168 | |||

| 10 x 0,75 | 116,16 | 24 x 0,21 | 10,4 | 217 | |||

| 12 x 0,75 | 132,48 | 24 x 0,21 | 10,9 | 231 | |||

| 18 x 0,75 | 202,56 | 24 x 0,21 | 12,8 | 314 | |||

| 25 x 0,75 | 268,80 | 24 x 0,21 | 15,2 | 434 | |||

| 34 x 0,75 | 332,16 | 24 x 0,21 | 17,1 | 529 | |||

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (app.value) mm | Overall diameter appr.mm | Weight appr. kg / km | |||

| 2 x 1 | 48,96 | 32 x 0,21 | 6,5 | 83 | |||

| 3 x 1 | 59,52 | 32 x 0,21 | 6,7 | 111 | |||

| 4 x 1 | 71,04 | 32 x 0,21 | 7,4 | 131 | |||

| 5 x 1 | 84,48 | 32 x 0,21 | 8,1 | 155 | |||

| 7 x 1 | 107,52 | 32 x 0,21 | 8,8 | 190 | |||

| 12 x 1 | 177,60 | 32 x 0,21 | 11,5 | 286 | |||

| 18 x 1 | 257,28 | 32 x 0,21 | 13,8 | 393 | |||

| 25 x 1 | 339,84 | 32 x 0,21 | 16,0 | 658 | |||

| 34 x 1 | 439,68 | 32 x 0,21 | 18,4 | 759 | |||

| 50 x 1 | 644,16 | 32 x 0,21 | 22,0 | 994 | |||

| 2 x 1,5 * | 62,40 | 30 x 0,26 | 7,1 | 97 | |||

| 3 x 1,5 * | 78,72 | 30 x 0,26 | 7,6 | 124 | |||

| 4 x 1,5 * | 96,00 | 30 x 0,26 | 8,2 | 166 | |||

| 5 x 1,5 * | 114,24 | 30 x 0,26 | 9,0 | 192 | |||

| 7 x 1,5 | 147,84 | 30 x 0,26 | 9,8 | 245 | |||

| 12 x 1,5 | 257,28 | 30 x 0,26 | 13,0 | 365 | |||

| 18 x 1,5 | 358,08 | 30 x 0,26 | 15,5 | 556 | |||

| 25 x 1,5 | 508,80 | 30 x 0,26 | 18,0 | 737 | |||

| 27 x 1,5 | 537,60 | 30 x 0,26 | 20,0 | 750 | |||

| 34 x 1,5 | 658,56 | 30 x 0,26 | 20,9 | 966 | |||

| 50 x 1,5 | 960,96 | 30 x 0,26 | 24,8 | 1.342 | |||

| 2 x 2,5 | 88,32 | 50 x 0,26 | 8,5 | 161 | |||

| 3 x 2,5 * | 113,28 | 50 x 0,26 | 9,0 | 187 | |||

| 4 x 2,5 | 141,12 | 50 x 0,26 | 9,9 | 241 | |||

| 5 x 2,5 | 168,96 | 50 x 0,26 | 11,0 | 274 | |||

| 7 x 2,5 | 242,88 | 50 x 0,26 | 12,0 | 344 | |||

| 12 x 2,5 | 391,68 | 50 x 0,26 | 15,9 | 407 | |||

| 4 x 4 | 238,08 | 56 x 0,31 | 11,6 | 307 | |||

| 5 x 4 | 276,48 | 50 x 0,31 | 12,8 | 370 | |||

| 2 x 6 | 163,20 | 84 x 0,31 | 12,5 | 180 | |||

| 4 x 6 | 329,28 | 84 x 0,31 | 14,0 | 402 | |||

| 5 x 6 | 386,88 | 84 x 0,31 | 15,5 | 506 | |||

| 4 x 10 * | 513,60 | 80 x 0,41 | 17,2 | 747 | |||

| 5 x 10 | 609,60 | 80 x 0,41 | 19,3 | 861 | |||

| 4 x 16 | 768,00 | 128 x 0,41 | 20,0 | 1.041 | |||

| 5 x 16 | 921,60 | 128 x 0,41 | 22,2 | 1.289 | |||

| 4 x 25 | 1.228,80 | 200 x 0,41 | 24,7 | 1.460 | |||

| 5 x 25 | 1.468,80 | 200 x 0,41 | 27,5 | 1.840 | |||