YSLYCY | PVC – Control Cable 0,6/1 kV, UV-resistant with Copper Braiding

Item descriptions

| Application: | Used as energy or connecting cable, as measuring, checking and control cable in machine tool manufacturing, plant engineering and on assembly ines and production lines.

Suitable fixed for fixed installation or flexible applications with free movement without forced motion and without tensile stress in dry and damp rooms, outdoors transferred considering the temperature range. Not for use in water or in the ground. For interference-free signal transmission for measuring, control and regulation technology, these cables with copper screening assures. |

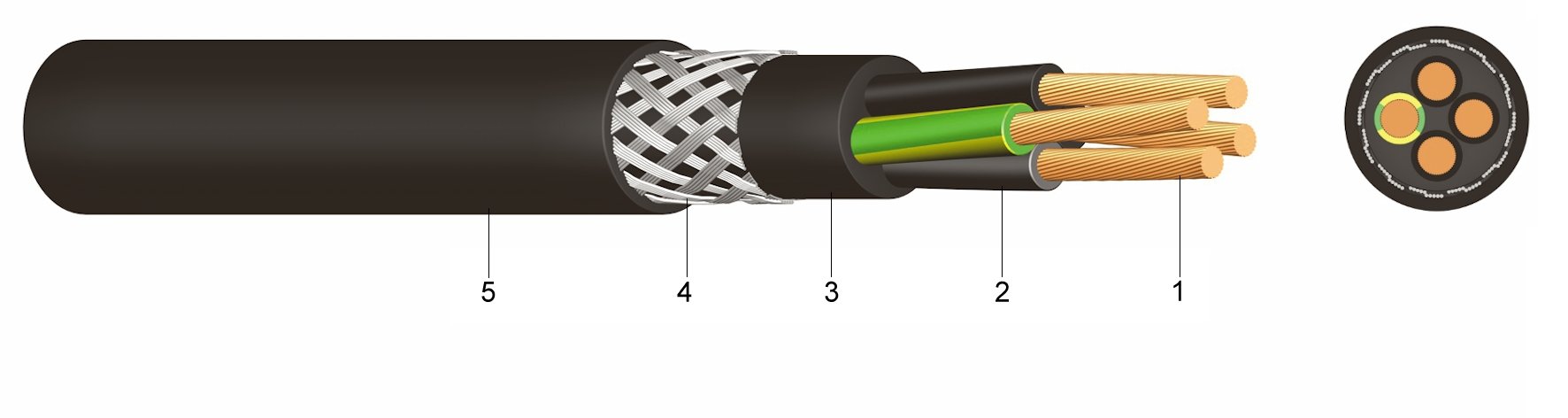

| Construction: |

1.....fine-stranded bare copper 2.....core insulation of polyvinylchloride (PVC) core identification JZ: 1 core green/yellow, other cores black with figures core identification OZ: every core black with figures 3.....inner sheath of polyvinylchloride (PVC) 4.....braiding of tinned copper round wires 5.....outer sheath of polyvinylchloride (PVC),black, increased oil resistant, flame retardant, UV-resistant |

| Standards: | DIN EN 60228 Class 5 (construction) |

| Nominal voltage Uo/U | [V] | 600 / 1000 Volt | |

| Test voltage | [V]AC | 6000 | |

| Temperature range | in motion | - 5°C till +70°C | |

| fixed | -40°C till +70°C | ||

| Bending radius | x diameter | 15 | |

| Flammability | standard | EN 60332-1 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (app.value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 2 x 0,75 | 41,28 | 24 x 0,21 | 10,5 | 183 |

| 3 x 0,75 | 54,72 | 24 x 0,21 | 10,9 | 210 |

| 4 x 0,75 | 67,20 | 24 x 0,21 | 11,4 | 238 |

| 5 x 0,75 | 78,72 | 24 x 0,21 | 12,1 | 272 |

| 7 x 0,75 | 96,96 | 24 x 0,21 | 12,9 | 315 |

| 12 x 0,75 | 168,00 | 24 x 0,21 | 15,8 | 464 |

| 2 x 1 | 51,84 | 32 x 0,21 | 10,8 | 198 |

| 3 x 1 | 66,24 | 32 x 0,21 | 11,2 | 228 |

| 4 x 1 | 85,44 | 32 x 0,21 | 11,8 | 261 |

| 5 x 1 | 93,12 | 32 x 0,21 | 12,6 | 300 |

| 7 x 1 | 117,12 | 32 x 0,21 | 13,3 | 335 |

| 12 x 1 | 204,48 | 32 x 0,21 | 16,4 | 522 |

| 18 x 1 | 280,32 | 32 x 0,21 | 19,4 | 628 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (app.value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 25 x 1 | 368,64 | 32 x 0,21 | 21,6 | 884 |

| 2 x 1,5 | 69,12 | 30 x 0,26 | 11,8 | 243 |

| 3 x 1,5 | 87,36 | 30 x 0,26 | 12,3 | 273 |

| 4 x 1,5 | 101,76 | 30 x 0,26 | 13,0 | 290 |

| 5 x 1,5 | 124,80 | 30 x 0,26 | 13,9 | 352 |

| 7 x 1,5 | 180,48 | 30 x 0,26 | 15,0 | 448 |

| 12 x 1,5 | 257,28 | 30 x 0,26 | 18,8 | 534 |

| 18 x 1,5 | 358,08 | 30 x 0,26 | 21,6 | 720 |

| 3 x 2,5 | 122,88 | 50 x 0,26 | 13,5 | 354 |

| 4 x 2,5 | 168,00 | 50 x 0,26 | 14,6 | 413 |

| 5 x 2,5 | 203,52 | 50 x 0,26 | 15,7 | 515 |

| 4 x 4 | 238,08 | 56 x 0,31 | 16,2 | 587 |

| 4 x 6 | 317,76 | 84 x 0,31 | 17,7 | 715 |

| 4 x 10 | 574,08 | 80 x 0,41 | 21,7 | 1.188 |

| 4 x 16 | 809,28 | 128 x 0,41 | 24,3 | 1.656 |