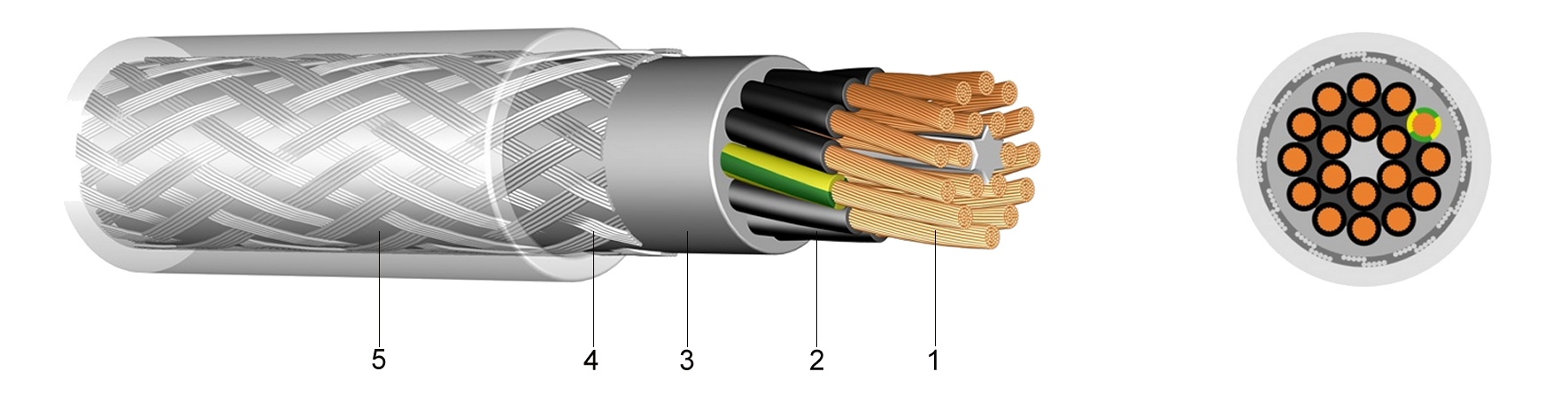

YSLYQY | PVC Control Cable with Steel Wire Braiding

Item descriptions

| Application: | Used as a power and control cable with increased mechanical stress-resistance for rough operating conditions. This cable is also suitable for fixed installations in vehicles, machines and hoists, etc. |

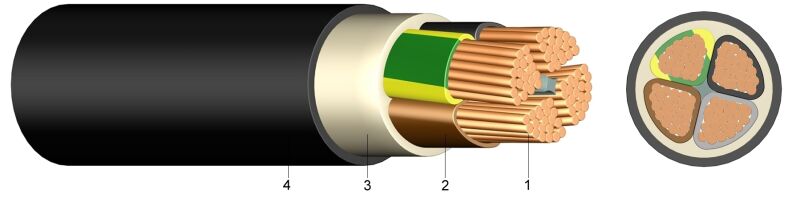

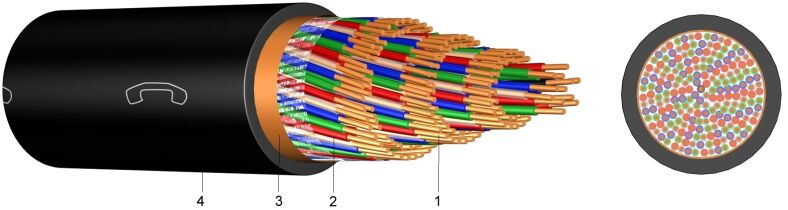

| Construction: | 1.....fine-stranded bare copper 2.....core insulation of polyvinylchloride (PVC) 3.....inner sheath of polyvinylchloride (PVC) 4.....braiding of galvanised steel wires 5.....outer sheath of polyvinylchloride (PVC), transparent, increased oil resistant |

| Standards: | adapted to DIN VDE 0281 DIN EN 60228 class 5 (construction) HD 308 S2 (core identification for coloured cores) core identification JZ: 1 core green/yellow, other cores black with figures core identification OZ: every core black with figures |

| Nominal voltage Uo/U | [V] | 300 / 500 Volt | |

| Test voltage | [V]AC | 2000 | |

| Temperature range | in motion | - 5°C till +70°C | |

| fixed | -40°C till +70°C | ||

| Operating temperature | short circuit | °C | 150 |

| Short circuit time | max. | [sec] | 5 |

| Bending radius | one time / fixed | x diameter | 6 |

| Bending radius | in motion | x diameter | 15 |

| Flammability | standard | EN 60332-1-2 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 2 x 0,75 | 14,40 | 24 x 0,21 | 7,5 | 73 |

| 3 x 0,75 | 21,60 | 24 x 0,21 | 7,8 | 82 |

| 4 x 0,75 | 28,80 | 24 x 0,21 | 8,2 | 89 |

| 5 x 0,75 | 36,00 | 24 x 0,21 | 8,8 | 101 |

| 7 x 0,75 | 50,40 | 24 x 0,21 | 9,1 | 127 |

| 12 x 0,75 | 86,40 | 24 x 0,21 | 11,5 | 187 |

| 18 x 0,75 | 129,60 | 24 x 0,21 | 13,3 | 258 |

| 25 x 0,75 | 180,00 | 24 x 0,21 | 16,3 | 370 |

| 34 x 0,75 | 244,80 | 24 x 0,21 | 18,0 | 473 |

| 50 x 0,75 | 360,00 | 24 x 0,21 | 20,5 | 649 |

| 2 x 1 | 19,20 | 32 x 0,21 | 7,7 | 79 |

| 3 x 1 | 28,80 | 32 x 0,21 | 8,0 | 90 |

| 4 x 1 | 38,40 | 32 x 0,21 | 8,5 | 106 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km |

| 5 x 1 | 48,00 | 32 x 0,21 | 9,1 | 119 |

| 7 x 1 | 67,20 | 32 x 0,21 | 9,7 | 145 |

| 12 x 1 | 115,20 | 32 x 0,21 | 12,1 | 226 |

| 18 x 1 | 172,80 | 32 x 0,21 | 13,8 | 311 |

| 25 x 1 | 240,00 | 32 x 0,21 | 16,9 | 438 |

| 34 x 1 | 326,40 | 32 x 0,21 | 18,5 | 561 |

| 50 x 1 | 480,00 | 32 x 0,21 | 22,4 | 794 |

| 2 x 1,5 | 28,80 | 30 x 0,26 | 8,3 | 96 |

| 3 x 1,5 | 43,20 | 30 x 0,26 | 8,5 | 117 |

| 4 x 1,5 * | 57,60 | 30 x 0,26 | 9,2 | 132 |

| 5 x 1,5 | 72,00 | 30 x 0,26 | 9,7 | 147 |

| 7 x 1,5 | 100,80 | 30 x 0,26 | 10,6 | 184 |

| 12 x 1,5 | 172,80 | 30 x 0,26 | 13,5 | 293 |

| 18 x 1,5 | 259,20 | 30 x 0,26 | 16,3 | 433 |

| 25 x 1,5 | 360,00 | 30 x 0,26 | 19,0 | 572 |

| 34 x 1,5 | 489,60 | 30 x 0,26 | 21,2 | 739 |

| 50 x 1,5 | 720,00 | 30 x 0,26 | 28,1 | 1.227 |

| 3 x 2,5 | 72,00 | 50 x 0,26 | 9,7 | 155 |

| 4 x 2,5 * | 96,00 | 50 x 0,26 | 10,7 | 191 |

| 5 x 2,5 | 120,00 | 50 x 0,26 | 11,5 | 224 |

| 7 x 2,5 | 168,00 | 50 x 0,26 | 12,6 | 285 |

| 12 x 2,5 | 288,00 | 50 x 0,26 | 16,6 | 460 |

| 18 x 2,5 | 432,00 | 50 x 0,26 | 19,3 | 654 |

| 25 x 2,5 | 600,00 | 50 x 0,26 | 23,2 | 891 |

| 4 x 4 * | 153,60 | 56 x 0,31 | 12,3 | 271 |

| 5 x 4 * | 192,00 | 56 x 0,31 | 13,8 | 330 |

| 7 x 4 | 268,80 | 56 x 0,31 | 15,4 | 442 |

| 4 x 6 | 230,40 | 84 x 0,31 | 14,5 | 379 |

| 5 x 6 ** | 288,00 | 84 x 0,31 | 16,4 | 474 |

| 7 x 6 | 403,20 | 84 x 0,31 | 17,7 | 615 |

| 4 x 10 | 384,00 | 80 x 0,41 | 18,0 | 608 |

| 7 x 10 | 672,00 | 80 x 0,41 | 21,6 | 920 |

| 4 x 16 | 614,40 | 128 x 0,41 | 21,8 | 945 |

| 5 x 16 ** | 768,00 | 128 x 0,41 | 23,4 | 1.123 |

| 7 x 16 | 1.075,20 | 128 x 0,41 | 26,0 | 1.494 |

| 4 x 25 ** | 960,00 | 200 x 0,41 | 25,1 | 1.349 |

| 4 x 35 ** | 1.344,00 | 280 x 0,41 | 29,6 | 1.839 |

| 5 x 35 ** | 1.680,00 | 280 x 0,41 | 32,0 | 2.197 |

| 4 x 50 ** | 1.920,00 | 400 x 0,41 | 34,3 | 2.605 |

| 4 x 70 ** | 2.688,00 | 356 x 0,51 | 38,5 | 3.453 |

| 4 x 95 ** | 3.648,00 | 470 x 0,51 | 43,0 | 4.544 |