H05VV5-F | PVC Control Cable Oil Resistant

Item descriptions

| Application: | In dry and wet locations for low and medium-level mechanical stress, but not in the open-air. To be used as a termination and connection cable in the control, measuring and signal technology. Suitable as a signal and impulse cable for control and inspection of industrial plants, production lines and machinery. |

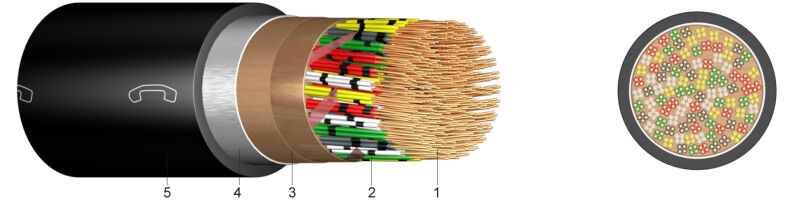

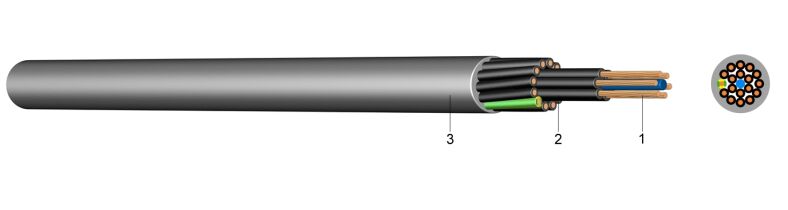

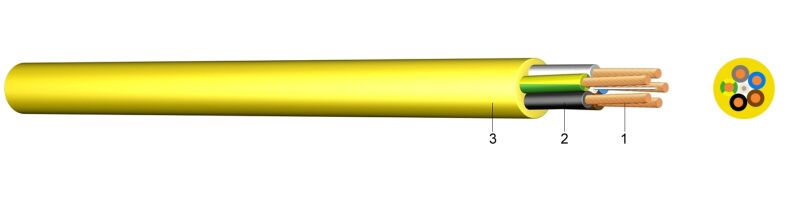

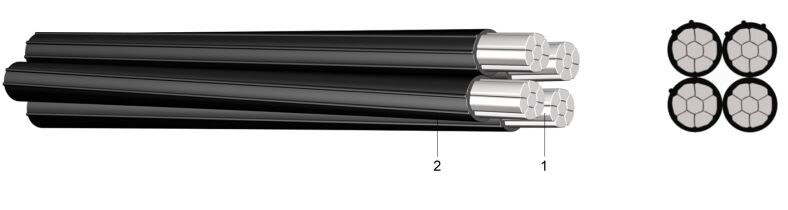

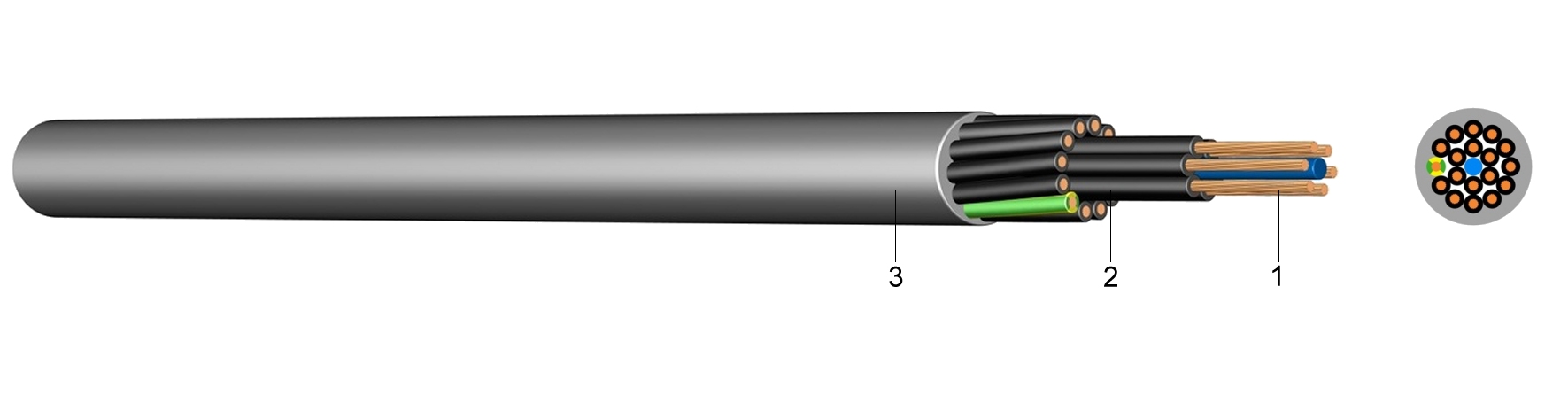

| Construction: | 1.....fine-stranded bare copper 2.....core insulation of polyvinylchloride (PVC-mixture YI2) 3.....outer sheath of polyvinylchloride (PVC-mixture YM2), grey |

| Standards: | DIN VDE 0281-part 13 DIN EN 60228 class 5 (construction) core identification: 1 core green/yellow, other cores black with figures |

| Nominal voltage Uo/U | [V] | 300 / 500 Volt | |

| Test voltage | [V]AC | 2000 | |

| Temperature range | in motion | -5°C till +70°C | |

| fixed | -40°C till +70°C | ||

| Operating temperature | short circuit | °C | 150 |

| Bending radius | one time / fixed | x diameter | 12,5 |

| Bending radius | in motion | x diameter | 15,0 |

| Oil-resistant | standard | EN 60811-2-1 | |

| Flammability | standard | EN 60332-1-2 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter mm | Weight appr. kg / km |

| 2 X 0,75 | 14,40 | 24 x 0,21 | 6,1 | 55 |

| 3 G 0,75 | 21,60 | 24 x 0,21 | 6,6 | 66 |

| 4 G 0,75 | 28,80 | 24 x 0,21 | 7,3 | 83 |

| 5 G 0,75 | 36,00 | 24 x 0,21 | 8,1 | 102 |

| 7 G 0,75 | 50,40 | 24 x 0,21 | 8,9 | 129 |

| 12 G 0,75 | 86,40 | 24 x 0,21 | 11,9 | 227 |

| 18 G 0,75 | 129,60 | 24 x 0,21 | 14,2 | 329 |

| 25 G 0,75 | 180,00 | 24 x 0,21 | 16,5 | 449 |

| 34 G 0,75 | 244,80 | 24 x 0,21 | 19,2 | 609 |

| 50 G 0,75 * | 360,00 | 24 x 0,21 | 23,2 | 893 |

| 2 X 1 | 19,20 | 32 x 0,21 | 6,5 | 63 |

| 3 G 1 | 28,80 | 32 x 0,21 | 6,9 | 77 |

| 4 G 1 | 38,40 | 32 x 0,21 | 7,7 | 97 |

| 5 G 1 | 48,00 | 32 x 0,21 | 8,5 | 120 |

| 7 G 1 | 67,20 | 32 x 0,21 | 9,4 | 152 |

| 12 G 1 | 115,20 | 32 x 0,21 | 12,6 | 268 |

| 18 G 1 | 172,80 | 32 x 0,21 | 15,0 | 389 |

| 25 G 1 | 240,00 | 32 x 0,21 | 17,5 | 533 |

| 34 G 1 | 326,40 | 32 x 0,21 | 20,4 | 721 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter mm | Weight appr. kg / km |

| 2 X 1,5 * | 28,80 | 30 x 0,26 | 7,6 | 90 |

| 3 G 1,5 | 43,20 | 30 x 0,26 | 8,2 | 110 |

| 4 G 1,5 | 57,60 | 30 x 0,26 | 9,1 | 138 |

| 5 G 1,5 | 72,00 | 30 x 0,26 | 10,1 | 172 |

| 7 G 1,5 | 100,80 | 30 x 0,26 | 11,1 | 219 |

| 12 G 1,5 | 172,80 | 30 x 0,26 | 14,9 | 388 |

| 18 G 1,5 | 259,20 | 30 x 0,26 | 17,9 | 565 |

| 25 G 1,5 | 360,00 | 30 x 0,26 | 20,9 | 775 |

| 34 G 1,5 | 489,60 | 30 x 0,26 | 24,3 | 1.051 |

| 3 G 2,5 | 72,00 | 50 x 0,26 | 9,7 | 162 |

| 4 G 2,5 | 96,00 | 50 x 0,26 | 10,7 | 205 |

| 5 G 2,5 | 120,00 | 50 x 0,26 | 12,0 | 256 |

| 7 G 2,5 | 168,00 | 50 x 0,26 | 13,2 | 328 |

| 12 G 2,5 | 288,00 | 50 x 0,26 | 17,8 | 581 |

| 18 G 2,5 | 432,00 | 50 x 0,26 | 21,3 | 848 |

| 34 G 2,5 | 816,00 | 50 x 0,26 | 29,0 | 1.584 |

| 4 G 4 * | 153,60 | 56 x 0,31 | 11,6 | 280 |

| 5 G 4 * | 192,00 | 56 x 0,31 | 14,1 | 340 |

| 7 G 4 * | 268,80 | 56 x 0,31 | 15,1 | 445 |

| 4 G 6 * | 230,40 | 84 x 0,31 | 16,8 | 450 |

| 5 G 6 * | 288,00 | 84 x 0,31 | 18,4 | 550 |