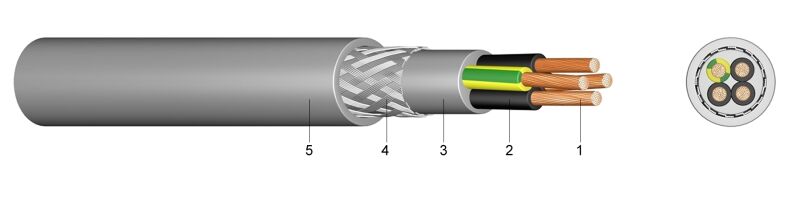

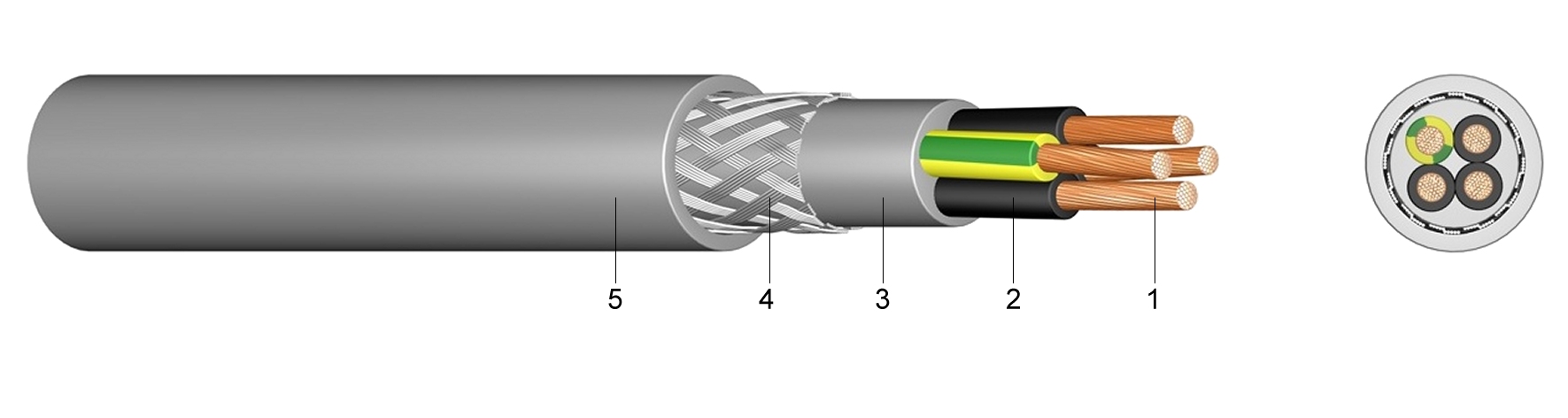

H05VVC4V5-K UL/CSA | PVC Control Cable with Copper Braiding, Oil Resistant, with UL and CSA Approbation (UL-Style 2587)

Item descriptions

| Application: | Suitable for dry, damp and wet locations but not in the open-air. It is used as a screened termination and connection cable in the control, measuring and signal technology. The copper braiding optimises protection against external interferences, like electromagnetic fields and stray frequencies. Suitable as a signal and impulse cable for control and inspection of industrial plants, machinery and working processes. |

| Construction: | 1.....fine-stranded bare copper 2.....core insulation of special polyvinylchloride (PVC) 3.....inner sheath of special polyvinylchloride (PVC) 4.....braiding of tinned copper wires 5.....outer sheath of special polyvinylchloride (PVC), grey |

| Information: | 0,50 mm² is equivalent to app. AWG 20 ( 0,519mm²) 0,75 mm² is equivalent to app. AWG 18 ( 0,823mm²) 1,00 mm² is equivalent to app. AWG 17 ( 1,040mm²) 1,50 mm² is equivalent to app. AWG 15 ( 1,650mm²) 2,50 mm² is equivalent to app. AWG 13 ( 2,630mm²) |

| Standards: | DIN VDE 0281-13, HD 21.13.S1 UL/CSA (UL-Style 2587) DIN EN 60228 class 5 (construction) core identification: 1 core green/yellow, other cores black with figures |

| Nominal voltage Uo/U | [V] | 600 Volt | |

| Test voltage | [V]AC | 3000 | |

| Temperature range | in motion | -5°C till +90°C | |

| fixed | -40°C till +90°C | ||

| Operating temperature | short circuit | °C | 150 |

| Short circuit time | max. | [sec] | 5 |

| Bending radius | one time / fixed | x diameter | 12,5 |

| in motion | x diameter | 15,0 | |

| Oil-resistant | standard | EN 60811-2-1 | |

| Flammability | standard | EN 60332-1-2 | |

| Insulation resistance | min. | [MOhm/km] | 20 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter mm | Weight appr. kg / km |

| 3 G 0,75 | 50,88 | 24 x 0,21 | 8,8 | 125 |

| 4 G 0,75 | 63,36 | 24 x 0,21 | 9,6 | 147 |

| 5 G 0,75 | 78,72 | 24 x 0,21 | 10,3 | 172 |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter mm | Weight appr. kg / km |

| 7 G 0,75 | 107,52 | 24 x 0,21 | 12,2 | 235 |

| 12 G 0,75 | 161,28 | 24 x 0,21 | 14,5 | 354 |

| 18 G 0,75 | 219,84 | 24 x 0,21 | 16,9 | 478 |

| 3 G 1 | 74,88 | 32 x 0,21 | 9,3 | 140 |

| 4 G 1 | 86,40 | 32 x 0,21 | 9,9 | 165 |

| 5 G 1 | 101,76 | 32 x 0,21 | 10,9 | 195 |

| 7 G 1 | 126,72 | 32 x 0,21 | 12,9 | 271 |

| 12 G 1 | 193,92 | 32 x 0,21 | 15,4 | 405 |

| 18 G 1 | 264,96 | 32 x 0,21 | 17,7 | 548 |

| 3 G 1,5 | 95,04 | 30 x 0,26 | 10,4 | 180 |

| 4 G 1,5 | 116,16 | 30 x 0,26 | 11,3 | 217 |

| 5 G 1,5 | 129,60 | 30 x 0,26 | 12,6 | 267 |

| 7 G 1,5 | 168,00 | 30 x 0,26 | 14,9 | 379 |

| 12 G 1,5 | 254,40 | 30 x 0,26 | 17,6 | 538 |

| 18 G 1,5 | 384,00 | 30 x 0,26 | 20,5 | 743 |

| 3 G 2,5 | 147,84 | 50 x 0,26 | 12,0 | 246 |

| 4 G 2,5 | 163,20 | 50 x 0,26 | 13,3 | 316 |

| 5 G 2,5 | 199,68 | 50 x 0,26 | 14,6 | 383 |