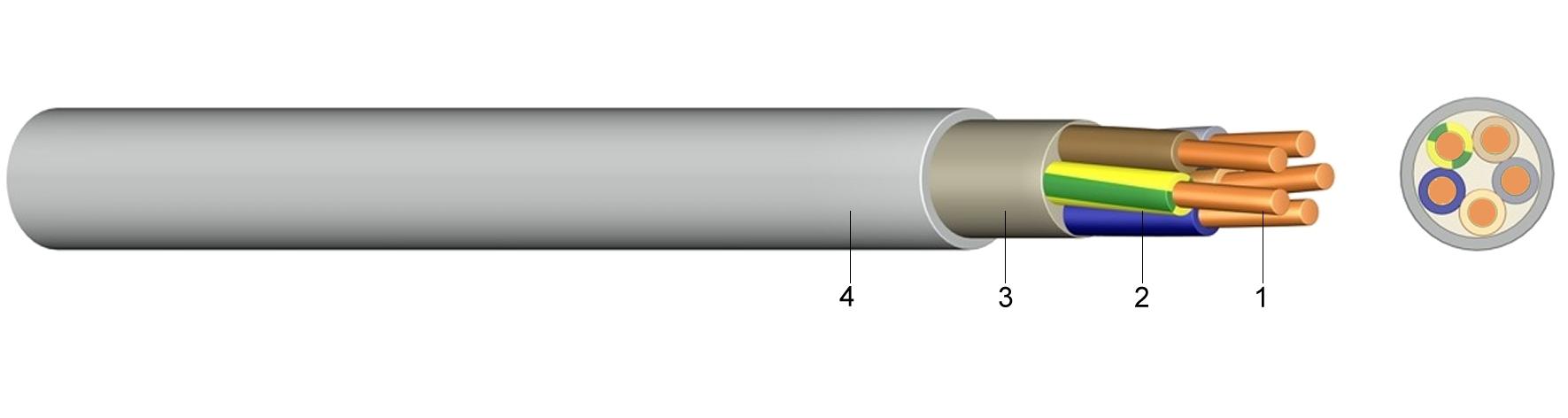

NHXMH | Halogen-Free Sheathed Wire with Improved Fire Behaviour

Item descriptions

| Application: | To be installed in buildings or industrial plants where many people and goods are concentrated. As they don't develop corrosive and halogen gases under the impact of fire, and the smoke and fume generation is also minimal, the damage caused is much smaller. They are destined for the installation on, in and under the wall-surface in dry, humid and wet locations as well as in brickwork or outdoors (when protected), but not directly into the earth. |

| Construction: | 1.....solid or stranded bare copper 2.....core insulation of cross-linked polyethylene (2XI1) 3.....core covering of a halogen-free filling compound 4.....outer sheath of halogen-free polymer (HM2), grey |

| Standards: | DIN VDE 0250-214 DIN EN 60228 class 1 and 2 (construction) HD 308 S2 (core identification) |

| Nominal voltage Uo/U | [V] | 300 / 500 Volt | |||||||||

| Test voltage | [V]AC | 2000 | |||||||||

| Temperature range | in motion | -5°C till +70°C | |||||||||

| Operating temperature | short circuit | °C | 160 | ||||||||

| Short circuit time | max. | [sec] | 5 | ||||||||

| Bending radius | in motion | x diameter | 12 | ||||||||

| Flammability | standard | EN 50266-2-4 EN 60332-1 IEC 60332-3 Kat.C | |||||||||

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Calorific potential kWh / m | Weight appr. kg / km | ||||||

| 1 x 4 | 38,40 | 1 x 2,25 | 6,0 | 0,42 | 105 | ||||||

| 1 x 6 | 57,60 | 1 x 2,76 | 6,4 | 0,44 | 150 | ||||||

| 1 x 10 | 96,00 | 1 x 3,56 | 7,4 | 0,53 | 200 | ||||||

| 1 x 16 RM | 153,60 | 7 x 1,70 | 8,6 | 0,63 | 295 | ||||||

| 2 x 1,5 | 28,80 | 1 x 1,38 | 8,7 | 0,39 | 113 | ||||||

| 2 x 2,5 | 48,00 | 1 x 1,38 | 9,5 | 0,45 | 145 | ||||||

| 3 x 1,5 | 43,20 | 1 x 1,38 | 9,1 | 0,43 | 130 | ||||||

| 3 x 2,5 | 72,00 | 1 x 1,78 | 9,9 | 0,50 | 168 | ||||||

| 3 x 4 | 115,20 | 1 x 2,25 | 11,2 | 0,63 | 234 | ||||||

| 3 x 6 | 172,80 | 1 x 2,76 | 12,7 | 0,79 | 319 | ||||||

| 3 x 10 | 288,00 | 1 x 3,56 | 15,3 | 1,09 | 494 | ||||||

| 4 x 1,5 | 57,60 | 1 x 1,38 | 9,7 | 0,50 | 152 | ||||||

| 4 x 2,5 | 96,00 | 1 x 1,78 | 10,6 | 0,58 | 201 | ||||||

| 4 x 4 | 153,60 | 1 x 2,25 | 12,5 | 0,83 | 296 | ||||||

| 4 x 6 | 230,40 | 1 x 2,76 | 13,7 | 0,92 | 388 | ||||||

| 4 x 10 | 384,00 | 1 x 3,56 | 16,5 | 1,29 | 606 | ||||||

| 4 x 16 RM | 614,40 | 7 x 1,70 | 19,4 | 1,68 | 917 | ||||||

| Number of cores and nominal cross section mm² | Price EUR / km J | Price EUR / km O | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Calorific potential kWh / m | Weight appr. kg / km | ||||

| 5 x 1,5 | 3.054,19 | 75 | 1 x 1,38 | 10,4 | 0,59 | 177 | |||||

| 5 x 2,5 | 3.915,25 | 125 | 1 x 1,78 | 11,5 | 0,69 | 241 | |||||

| 5 x 4 | 4.989,22 | 200 | 1 x 2,25 | 13,5 | 0,96 | 352 | |||||

| 5 x 6 | 6.167,67 | 300 | 1 x 2,76 | 15,3 | 1,16 | 485 | |||||

| 5 x 10 RE | 8.380,21 | 500 | 1 x 3,56 | 18,0 | 1,56 | 731 | |||||

| 5 x 10 RM | 8.799,00 | 500 | 7 x 1,35 | 18,0 | 1,56 | 731 | |||||

| 5 x 16 RM | 16.108,42 | 800 | 7 x 1,70 | 22,2 | 2,23 | 1.168 | |||||

| 7 x 1,5 | 3.561,54 | 105 | 1 x 1,38 | 11,1 | 0,65 | 220 | |||||

| 7 x 2,5 | 4.565,67 | 175 | 1 x 1,78 | 12,7 | 0,82 | 311 | |||||

| 12 x 1,5 | 5.078,18 | 180 | 1 x 1,38 | 14,8 | 1,11 | 391 | |||||