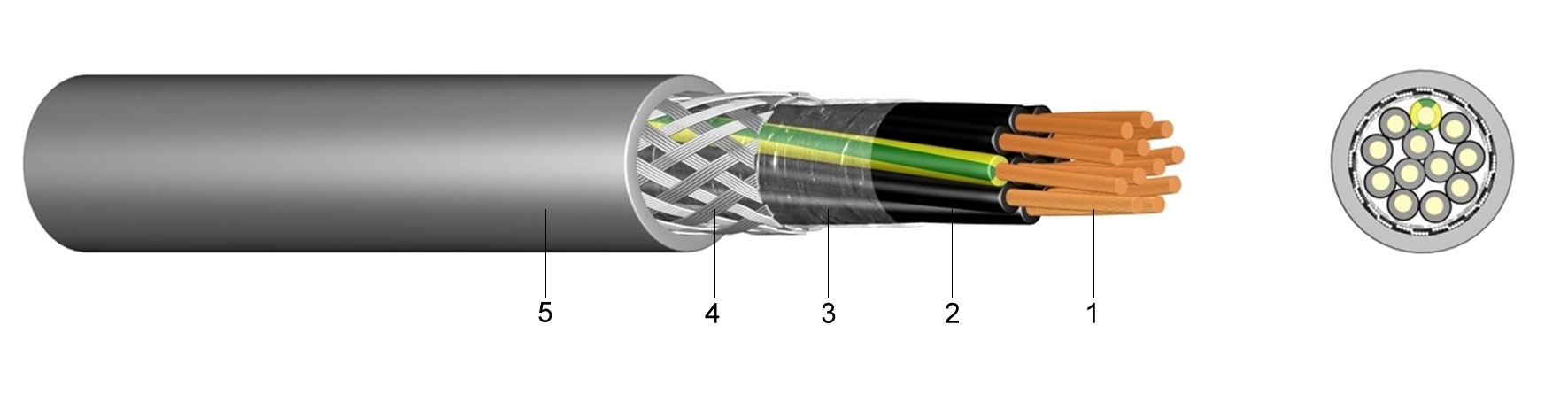

HSLCH FRNC | Halogen-Free Control Cable with EMV-Optimised Braided Screen and Improved Fire Behaviour - FRNC

Item descriptions

| Application: | For installations in dry, humid and wet locations but not outdoors. These cables are used for fix or for flexible applications - but not with high tensile load and for forced bending. Suitable as a signal and impulse cable in the control, measuring and signal technology. The copper braiding optimises protection against external interferences, like electromagnetic fields and stray frequencies. |

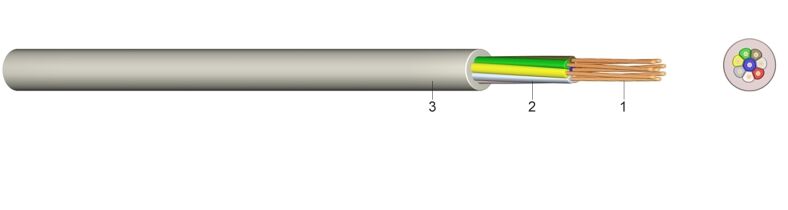

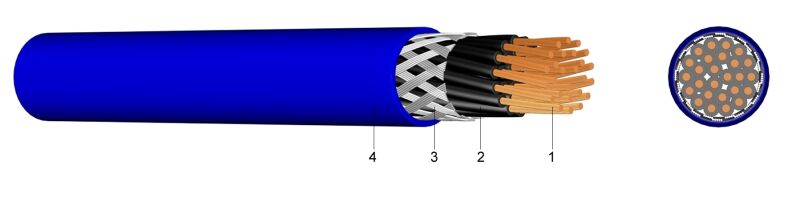

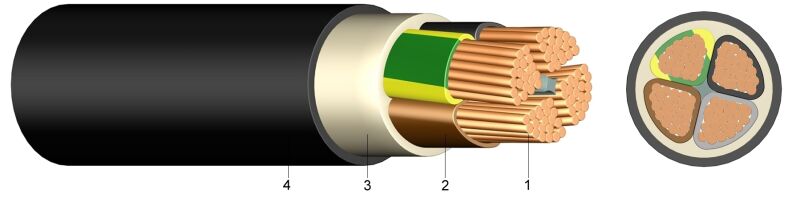

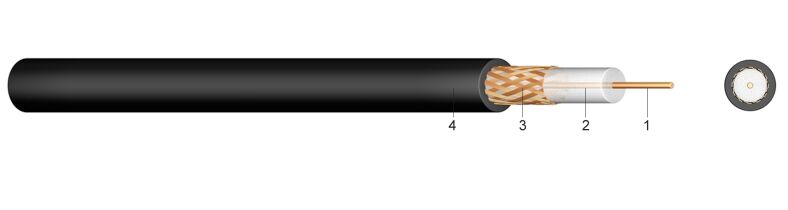

| Construction: | 1.....fine-stranded bare copper 2.....core insulation of halogen-free, cross-linked polyolefin copolymere 3.....wrapped in a plastic foil 4.....screen of tinned copper wire braiding 5.....outer sheath of halogen-free, cross-linked polyolefin copolymere, grey |

| Standards: | adapted to DIN EN 50266-2-4 and 50267-2-2 DIN EN 60228 class 5 (construction) core identification JZ: 1 core green/yellow, other cores black with figures core identification OZ: every core black with figures |

| Nominal voltage Uo/U | [V] | 300 / 500 Volt | |

| Test voltage | [V]AC | 2000 | |

| Temperature range | in motion | -5°C till +70°C | |

| fixed | -30°C till +70°C | ||

| Operating temperature | short circuit | °C | 150 |

| Short circuit time | max. | [sec] | 5 |

| Bending radius | in motion | x diameter | 15 |

| Flammability | standard | EN 50266-2-4 EN 60332-1 IEC 60332-3 Kat.C |

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km | |||||

| 2 x 0,75 | 39,36 | 24 x 0,21 | 6,2 | 55 | |||||

| 3 x 0,75 | 48,96 | 24 x 0,21 | 6,5 | 70 | |||||

| 4 x 0,75 | 58,56 | 24 x 0,21 | 7,0 | 87 | |||||

| 5 x 0,75 | 69,12 | 24 x 0,21 | 7,7 | 106 | |||||

| 7 x 0,75 | 85,44 | 24 x 0,21 | 8,3 | 129 | |||||

| 12 x 0,75 | 132,48 | 24 x 0,21 | 10,9 | 211 | |||||

| 18 x 0,75 | 202,56 | 24 x 0,21 | 12,7 | 307 | |||||

| 25 x 0,75 | 268,80 | 24 x 0,21 | 15,0 | 413 | |||||

| 34 x 0,75 | 319,68 | 24 x 0,21 | 17,3 | 523 | |||||

| 2 x 1 | 48,96 | 32 x 0,21 | 6,5 | 79 | |||||

| 3 x 1 | 59,52 | 32 x 0,21 | 6,8 | 88 | |||||

| 4 x 1 | 71,04 | 32 x 0,21 | 7,4 | 106 | |||||

| Number of cores and nominal cross section mm² | Copper figure kg/km | Cond. construction (appr. value) mm | Overall diameter appr. mm | Weight appr. kg / km | |||||

| 5 x 1 | 84,48 | 32 x 0,21 | 8,1 | 124 | |||||

| 7 x 1 | 107,52 | 32 x 0,21 | 8,8 | 155 | |||||

| 12 x 1 | 177,60 | 32 x 0,21 | 12,3 | 232 | |||||

| 18 x 1 | 257,28 | 32 x 0,21 | 14,7 | 332 | |||||

| 25 x 1 | 342,72 | 32 x 0,21 | 16,0 | 460 | |||||

| 2 x 1,5 | 62,40 | 30 x 0,26 | 7,1 | 91 | |||||

| 3 x 1,5 | 78,72 | 30 x 0,26 | 7,5 | 112 | |||||

| 4 x 1,5 | 96,00 | 30 x 0,26 | 8,5 | 141 | |||||

| 5 x 1,5 | 114,24 | 30 x 0,26 | 8,9 | 161 | |||||

| 7 x 1,5 | 147,84 | 30 x 0,26 | 9,9 | 206 | |||||

| 12 x 1,5 | 257,28 | 30 x 0,26 | 14,7 | 323 | |||||

| 18 x 1,5 | 358,08 | 30 x 0,26 | 15,5 | 517 | |||||

| 25 x 1,5 | 508,80 | 30 x 0,26 | 18,1 | 705 | |||||

| 3 x 2,5 | 113,28 | 50 x 0,26 | 9,0 | 157 | |||||

| 4 x 2,5 | 141,12 | 50 x 0,26 | 9,9 | 201 | |||||

| 5 x 2,5 | 168,96 | 50 x 0,26 | 11,0 | 248 | |||||

| 7 x 2,5 | 242,88 | 50 x 0,26 | 13,9 | 306 | |||||

| 12 x 2,5 | 353,28 | 50 x 0,26 | 15,9 | 499 | |||||

| 4 x 4 | 238,08 | 51 x 0,30 | 11,7 | 291 | |||||

| 5 x 4 | 234,24 | 51 x 0,30 | 12,8 | 364 | |||||

| 4 x 6 | 329,28 | 76 x 0,30 | 13,9 | 437 | |||||

| 7 x 6 | 509,76 | 76 x 0,30 | 18,2 | 700 | |||||

| 4 x 10 | 574,08 | 77 x 0,40 | 17,4 | 685 | |||||

| 5 x 10 | 595,20 | 77 x 0,40 | 19,5 | 824 | |||||

| 4 x 16 | 809,28 | 119 x 0,40 | 20,6 | 972 | |||||

| 4 x 25 | 1.174,08 | 182 x 0,40 | 25,3 | 1.443 | |||||